Call us now +91-70489 93388

-

Email nowsupport@adxelauto.com

-

Address1st Floor, Khasra No. 180/2, Akbarpur Bahrampur, Taj Highway, Ghaziabad, India

Call us now +91-70489 93388

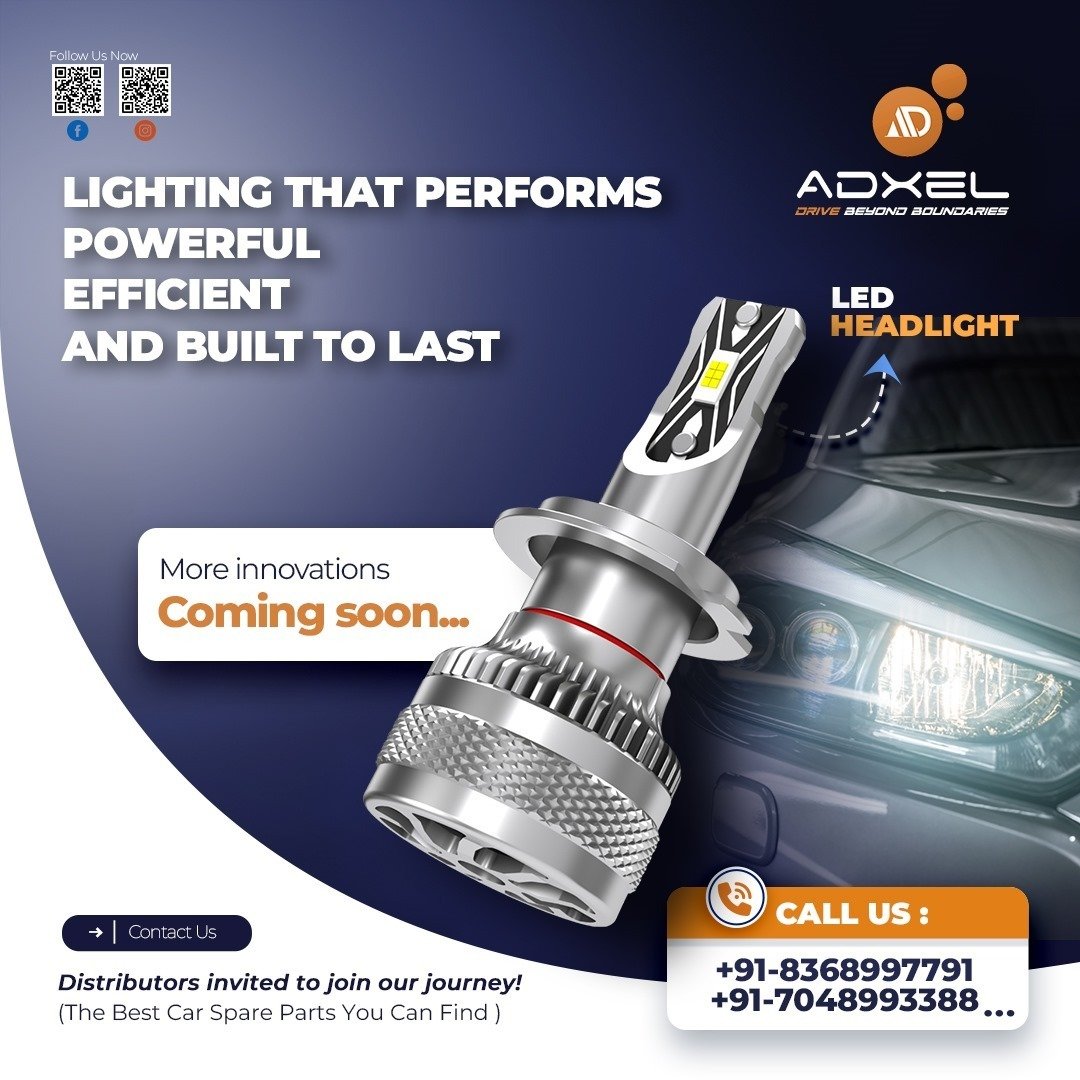

Quality LED bulbs from reputable manufacturers are essential for brand building and business growth in the auto lighting market. A reliable headlight bulb manufacturer not only offers high-end products but also provides exceptional after-sales service and exclusive benefits for their distributors.

While product quality is a crucial consideration when choosing a headlight bulb supplier, it can be challenging to determine quality solely by purchasing a sample or relying on online customer reviews, which may not reflect the true product situation.

However, in this blog, we present the manufacturing process of premium LED headlight bulbs from NAOEVO, a professional automotive lighting manufacturer based in China. This comprehensive overview allows wholesalers, distributors, and retailers to gain a thorough understanding of their product quality before purchasing in bulk.

The main components of an LED headlight bulb encompass the LED chip, lamp body, circuit board, and fan.

The LED chip serves as the light source, providing bright and efficient illumination. The lamp body mostly is made of 6063 aluminum to protect the components while ensuring proper heat dissipation. The circuit board controls the electrical current and voltage, ensuring stable performance. The fan aids in cooling the bulb, preventing overheating and prolonging its lifespan.

Together, these components create a reliable and durable LED headlight bulb that delivers enhanced visibility, energy efficiency, and longevity for a safer and more efficient lighting solution in automotive applications.

With today’s innovation, there is more creativity allowed in researching and developing LED headlight bulbs. Before manufacturing takes place, we will do an in-depth market research for our new products to understand the market trends, customer needs, and technological advancements.

If the LED bulbs meet the requirements of consumers, we proceed to design, test, and produce. If they don’t pass the test, they are sent back for redesigning, redevelopment, and retesting. We ensure the bulbs have high performance in every aspect before mass production.

Integrating sphere ensures accurate measurement of optical parameters such as luminous flux and color rendering index. Spectrometers analyze the spectral output of the LED bulb. Light Beam Pattern Test System visualizes light spread and lux in a 180-degree dark room. Thermal chambers assess heat dissipation capability. Vibration and shock testers simulate road conditions for durability testing.

Once design and development are complete, we begin raw material procurement and inspection. After ensuring material quality, we use SMT machines to precisely place LED chips on the base board, enabling high-speed and accurate assembly.

We test LED chips using a Regulated DC Power Supply to ensure consistent output. The chips are connected and tested under specific voltage to check brightness, stability, and uniformity.

Silicone grease is evenly applied on the copper substrate to improve heat dissipation. This step ensures more than 80% coverage, providing strong bonding with the aluminum body.

The LED light source is installed into the aluminum body. Our QR team selects high-quality aluminum and follows strict procedures to maintain standards and protect components.

Technicians install rivets using rivet guns to create a strong bond. This step helps the bulb resist vibrations, water, and high temperatures.

We use automatic machines to solder components on the driver board. This ensures faster and more stable soldering compared to manual tin-coating, reducing the chance of faulty connections.

Driver boards are inserted manually into the bulb. They control power supply and ensure consistent current to the LED chips, enabling reliable illumination.

Wires are carefully soldered to terminals using heat and solder. This ensures a stable electrical connection to power the bulb efficiently.

The internal fan is connected to the driver board. It helps dissipate heat, maintaining proper temperature and extending the bulb’s lifespan.

Each bulb is inspected for LED chip performance and fan functionality. Any defects are traced and corrected. We aim for zero defects in every batch.

Glue is injected automatically to secure the driver components. It improves water resistance and durability of the bulb, enhancing performance.

The fan is fixed inside the housing and aligned with the heat sink. Secure installation and proper wiring are ensured for optimal operation.

All bulbs undergo 72-hour testing to ensure durability and performance under continuous operation. This reduces failure rate in the market.

Bulbs are gently cleaned with soft, lint-free cloths to remove any residue and maintain a clean finish before final packaging.

The sealing ring and chuck are installed. They match original stock designs to ensure easy and secure installation in vehicles.

Our logo is printed using a laser printer. We also offer free customized logo printing services for clients as part of our OEM support.

Each LED headlight bulb is packaged with certification and manuals in protective materials to prevent damage during shipping.

We implement four-stage inspection including raw material check, semi-finished inspection, aging inspection, and final QC. Our focus is always on “ZERO” defect rate.

Our labs are equipped with SMT machines, soldering machines, thermal ovens, integrating spheres, and a 25-meter lighting test lane, enabling world-class manufacturing quality.

Our factory in Baiyun District spans 10,000 square meters with 200 workers and 20 engineers. We produce over 2 million headlight kits annually with over 100,000 kits in stock for fast delivery.

NAOEVO offers OEM services including logo printing, custom packaging, light colors, and more, tailored to specific client requirements.

We offer our distributors early access to new products, better pricing, promotional materials, display racks, and full marketing support to grow their business effectively.

Our goal is to help our partners succeed and lead in the automotive lighting industry.